Collection

To date, Takenaka Carpentry Tools Museum has collected about 30,500 pieces of carpentry tools and related materials from Japan and overseas in order to pass on the skills and minds of craftsmen who supported architectural culture to future generations. Here, we will introduce some of them in a gallery format.

Japanese carpentry tools

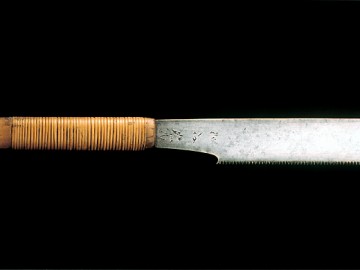

Vertical saws| Seibei Taniguchi

Japanese carpentry tools, Hikiyaguchi Seibei Edo period

Taniguchi had a sales channel in Kansai as a saw blacksmith in Fushimi, Kyoto. It is said that during the Tenmei era (1781-1788), production was the most popular. It retains an old style, such as a warped back and a curved saw tip, and is thought to be from the early Edo period.

Double blade saw| Tetsunosuke Miyano

Japanese carpentry tool double-edged saw "Autumn no Shirabe" Miyano Tetsunosuke (2nd generation) Showa period

The second generation Tetsunosuke Miyano (1901-1996) is a saw blacksmith of Miki Banshu. He helped the family business from the age of 11, and in 1938 he was named the second generation Tetsunosuke Miyano. It is said that he was full of blacksmith talent and quickly overtook the skills of his brothers and children. Throughout his life, he devoted himself to protecting traditional techniques and conveying them to the composition. The double-edged saw in the photo was trained in 1954 for Yoshio Sasase, a master of Kobe.

Gagari | Heijiro Miyano

Japanese carpentry gong, Miyano Taira, the third generation, Showa era

The Miyano family is a famous saw blacksmith of Miki. The first Jiro Taira was said to be three people along with Jiro Nakayahira in Edo and Sukezaemon Nakaya in Aizu. Since the Meiji era, he has been specialized in carpentry, and only one blade cut, one blade gong, and two blade saws, and did not manufacture hole grinding.

Push saw| Hisasaku Nakaya

Meiji period, Japanese carpentry tools

Hisasaku Nakaya was the last master craftsman of the Tamako era and lived in Koishikawa, Tokyo. It is reported that he learned the oil baking method based on the smell of tempura oil flowing from the workplace of his teacher, Taira Nakaya. It is known for its unique thick leaves called Sasaba mei.

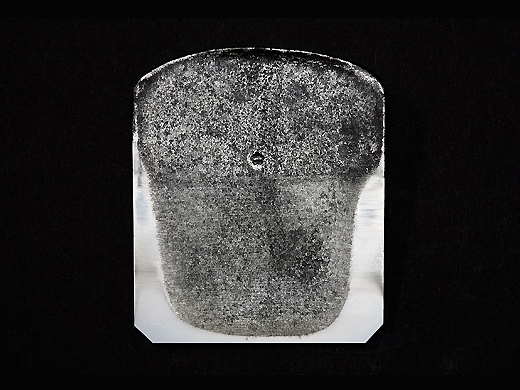

Oirichisel| Zensaku

Japanese carpentry tools Daiirichisel Yoshisaku Matsubara (the third generation) Showa period

The eldest son of the first Zensaku succeeded the second generation, and the second younger brother succeeded the third generation. It was produced from the beginning of the Taisho era to the 20s. The sharpness of the chisel was outstanding, and it was said that the soft Yoshino cedar was cut and cut brilliantly. In addition, he had excellent skills to train the vortex of the bullion. Around 1953, when the location was unknown, it came to be called 'the phantom Zensaku.'

Edo bear chisel| Chiyozuruzehide

Japanese carpenter tool Edo bear chisel Chiyo Tsuruzehide Showa period

It was said that the tools trained by master craftsman Chiyozuruzehide were sharp but expensive to celebrate household miniature shrine. The carpenter Edo Kuma (Jiro Kato), who knew the work, wrote a request for an order with a desperate wish even though he had no acquaintance, and sent a copy of his family register. In response to his heart, Korehide trained 15 large chisels, built a train fare, and went to Osaka by night. The group chisel was damaged by the war after the death of Edo bear, but it went around and was preserved in the museum.

Wide chisel| Shigefusa

Japanese carpentry tools Hiroshichisel Shigefusa (Aemon Wakabayashi) from the late Edo period to the early Meiji period

Shigefusa was a Japanese blacksmith of Aizu Wakamatsu, which had been around the 17th century, and his 15th eldest son Anemon (16th), who had trained as a swordsmith in Osaka, started cutting blades again. Along with Kusakabe Shigemichi, he became a founder of Aizu Uchihamono. Aizu has long been the center of cutting blade production in eastern Japan, but has missed the modernization of production and sales, and traditional techniques have been lost.

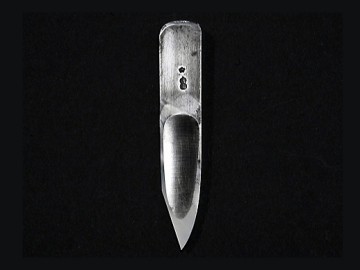

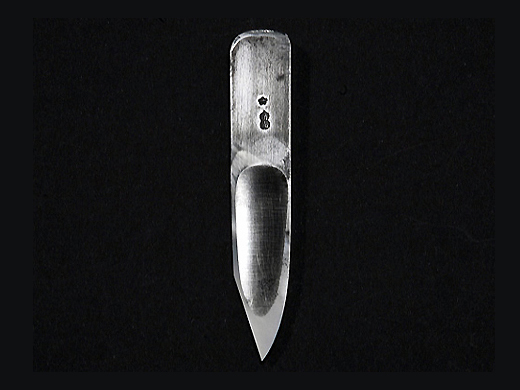

Wide chisel| Sakuhiro

Japanese carpenter tool Hiroshichisel left Hisahiro (Umejiro Kashiwagi) from the middle of the Meiji period to the end of the Taisho era

Hisahiro was a disciple of the swordsmith Kiyohiro, who became a chisel blacksmith after the Meiji Restoration. It opened in 1897 at headquarters in Tokyo. Because Hisahiro was named as collateral for debt, he began to use a famous engraving with Hisahiro in the gourd with the left letter Hisahiro in the gourd. The quenching of steel and the sticking of gold are excellent.

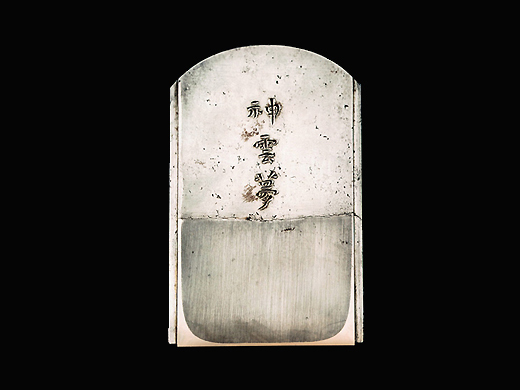

'Shinun Yume' Chiyozuruzehide

Japanese carpenter tool plane blade "Shinun Yume" Chiyozuruzehide Showa period

Chiyozuruzehide (1874-1957) is regarded as a master craftsman who has never been seen. In 1884, at the age of 10, he entered his uncle, Zenichi Ishido. Shuichi Ishido, who divided his popularity, was a cousin. Independence in 1893. The price was high, but it became popular for its sharpness. Known as a chisel blacksmith, he worked on various types of tools and always finished up to the area of art. It is said that these works have sharpness and sophisticated dignity.

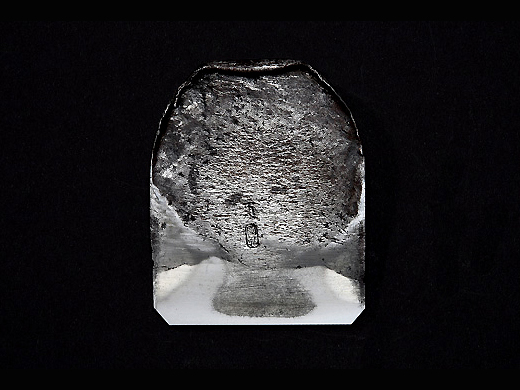

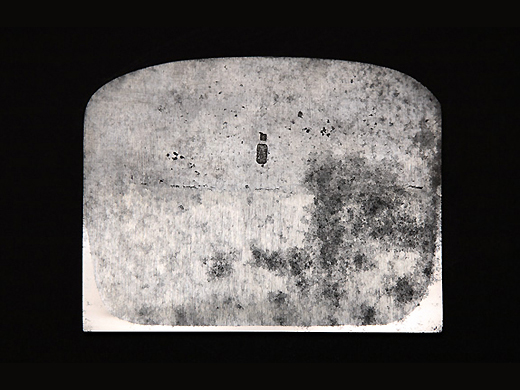

'Tanyuki' Chiyozuruzehide

Japanese carpentry tool plane blade "Tanyuki" Chiyozuruzehide Showa period

A plane blade trained by legendary master craftsman Chiyozuruzehide. Korehide does all the work by hand, and that's it. It is said that in the process, it took a lot of effort to finish a tool. It is said that he paid special attention to the materials used, and used traditional Japanese iron, which took time to sort the bullion. The reason why Korehide's tools were so expensive was probably because they included such effort.

Plane blade| Shuichi Ishido

Japanese carpentry tool plane blade Hideichi Ishido Showa era

The Ishido family was a swordsmith held by the Yonezawa clan, and in 1874 he turned to a tool blacksmith. Shuichi studied under his father, Zenichi Ishido, together with his cousin Chiyo Tsuruzenhide, and jointly studied the tools of masters. Unlike Korehide, it was called "Unnamed Ishido" without cutting its name, but it is distinguished from other planes due to the unique shape of the comb type and Yabane crest and its sharpness.

Plane blade | Yoshihiro

Japanese carpenter tool plane blade Yoshihiro Late Edo period to mid-Meiji period

Yoshihiro, along with his older brother Kunihiro, moved from Sanjo Echigo to Hatchobori in Edo at the end of the Edo period, gaining fame. At that time, it was said, "The chisel is Kunihiro, the plane is Yoshihiro," and he was praised as a master of plane making. Master craftsman It is said that Chiyozuruzehide was also private and photographed the shape of the plane body.

Plane blade | Kunihiro

Japanese carpenter tool plane blade Kunihiro Late Edo period to mid-Meiji period

A brother blacksmith who played an active part with his younger brother Yoshihiro from the late Edo period to the middle of the Meiji era. Shape-making He was said to be a master, and made tools with flowing lines and reasonable flesh, which had a great influence on future tool blacksmiths. It is said to be a master of chisel production, but the plane also has a powerful and elegant form.

Plane blade| Zensaku

Japanese carpenter tool plane blade Yoshisaku Matsubara in the Showa period

A plane blade trained by Kansai master craftsman Zensaku Matsubara (Shigejiro). Zensaku had outstanding skills, but he was said to have been a craftsman-like and an oligarch. It is said that he liked sake and saw Yoreyore's work clothes and walking around the town of Osaka with a rope belt, but he disappeared around 1953.

Plane blade | Umeichi

Japanese carpenter tool plane blade Umeichi Late Meiji period to early Showa period

Umeichi was the seventh generation of Kaga Hyakumangoku swordsmith Kiyomitsu. He moved to Osaka in 1965 and lived in Fukushima. At that time, he was a master craftsman who gained fame along with 'Zensaku.' Around 1935, he stopped blacksmithing at old age.

Wakitori plane blade | Umeichi

Japanese carpentry tools Wakitori plane blades from the latter half of the Meiji era to the early Showa era

Umeichi was the seventh generation of Kaga Hyakumangoku swordsmith Kiyomitsu. He moved to Osaka in 1965 and lived in Fukushima. At that time, he was a master craftsman who gained fame along with 'Zensaku.' Around 1935, he stopped blacksmithing at old age. The photo shows the blade of a plane that cuts off the side (side) of the groove.

Overseas carpentry tools

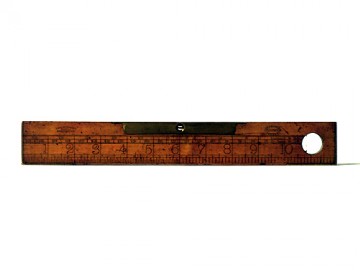

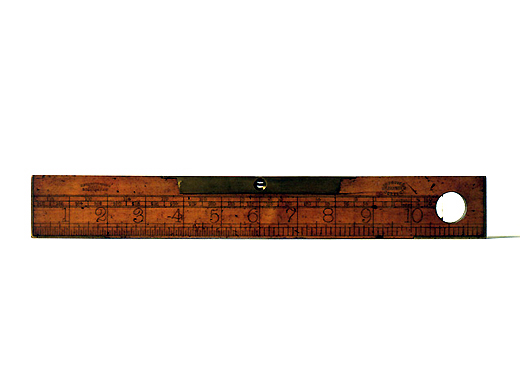

Horizontal instruments

Overseas carpentry tools Horizontal instruments U.K. 19th century fittings craftsmen 305×12×41mm

The horizontal device is used to check whether the surface of the member or the assembled state is horizontal. This product has an inch scale and can be used as a measure.

Compass

Overseas carpentry tool compass 18th century Swiss Architecture carpenter 490×260×62mm

It can be fixed with screws in order to keep the open state constant.

Frame saw

Overseas carpentry tool frame saw 19th century French furniture craftsman 380×218×17mm

Use by twisting the string to extend the saw body.

Saw

Overseas carpentry tools saw U.K. 19th century Architecture carpenter 780×23×190mm

The width of the saw and the appearance of the eyes is the opposite of Japan. The grip is attached directly to a wide saw body.

Chisel

Overseas carpentry tool chisel 18th century Swiss architecture carpenter 334×40×40mm

It is used to process hozo holes in building components.

Determine plane

Overseas carpentry tools determined plane U.K. 19th century fittings craftsman 240×54×141mm

Used when scraping a step (shakuri) at the end of the board material or the like. The width and depth of the step can be adjusted with screws.

Groove cut plane

Overseas carpentry tool groove cut plane Austria 1817 barrel craftsman 248×340×140mm

It is used to cut the groove inside the barrel to stop the mirror plate.

Axe

Overseas carpentry tools are hanging Axe France 19th century wooden shoemakers 430×260×75mm

Use the material to get rough.

Korean ink pot

Overseas carpentry tools sumitsubo Year of Korean Peninsula production unknown 163 × 100 × 101mm

Many traditional Korean ink pots consist of three parts, with a spindle or cube, a circular or spherical part of the spindle part, and a spindle part of the spindle part as a beast head. One of the features is that the groove for storing ink at the bottom is cut. The photo is based on the legendary animal hete.

Chinese ink pot

Overseas carpentry tools Chinese ink pots Year unknown 216×148×113mm

In the vast China, various forms of ink pot can be seen. They can be classified into butt split type, one-arm type, two-arm closed type, and bottom closed type according to structure and shape. The bottom-closed type can be further divided into (a) elevated type (b) one-letter type (c) sculpture type, etc. The photo shows a ink pot that can be classified into a high-rise shape, and the elegant sculpture and the overall shape are beautifully designed.

Thai ink pot

Overseas carpentry tools sumitsubo Thai production year unknown 173×143×120mm

The photo is an ink pot collected in central Thailand with a motif of a Shinto bird. The structure and function of Thai ink pots are the same as in Japan and China, but they tend to emphasize the shape of motifs, and there are other sculptures of monkeys, frogs, and rabbits.

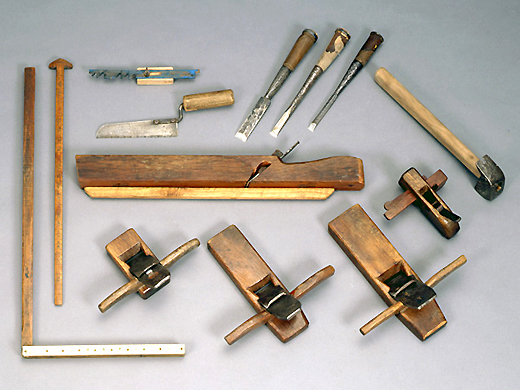

Chinese tools

Overseas carpentry tools Chinese carpentry tools Chinese carpentry tools Chinese 20th century

It is thought that the origin of Japanese carpentry tools is in China, but today there are various differences in shape and usage. Above all, the Chinese plane is used for thrust, so it is very different from the Japanese plane, such as with a handle.

Chinese frame saw

Overseas carpentry tools Chinese frame saw China 20th century

It is thought that the origin of Japanese carpentry tools is in China, but today there are various differences in shape and usage. Cut the wood by using a framed saw so that you can easily see the saw at first glance. In Japan, in the 14th to 15th centuries when vertical saw saws were introduced, a frame saw called a saw was used.

Tools of Iran

Overseas carpentry tools Iranian carpentry tools Iran 20th century

I don't know much about carpentry tools in the Middle East. If you look at the Iranian tools in the photo, you can see that the plane is influenced by Europe, but the saw has eyes for pulling, and it is different from the European saw that it is used for thrust.

Tools of Nepal

Overseas carpentry tools Nepal carpentry tools Nepal (Bandipuru) 20th century

Nepal is adjacent to China and India, and is a country with a mix of diverse cultures. In carpentry tools, there are also influences such as Chinese and Tibet culture that came across the mountainous areas of the north, and European colonial culture that came from India. The handle of the saw is Western, but it is used to pull it, and the plane is Chinese, but it has the characteristics of using it by two people.

Tools of Bhutan

Overseas carpentry tools Bhutan carpentry tools Bhutan 20th century

Bhutan is a small country between India and China. At the foot of the Himalayas, such as Bhutan, northern India, and Nepal, there are people who build wooden temples and dwellings. It is interesting that the right hand in the photo is a thread roll and the left hand is a hammer, but it has a primitive force.

Customs and literature materials

Ritual tools

Customs and literature materials ritual tools during the Edo period

The ceremony held at each milestone of construction work was one of the most important tasks for the carpenter's master. During the ceremony, carpenter tools for rituals decorated with gold leaf and lacquer were displayed on the altar to create a solemn atmosphere. In addition, since ancient times, chona, ink pot, kushaku, etc. have been used for ritual tools.

Inhanki

happi coat: Showa Period

Shirushihanten is a half-cloth with dyed occupations and brand names, and craftsmen working outdoors such as carpenters and Sakan plasterers from the late Edo period to the Meiji period began to wear them like uniforms along with belly, crotch, and tabi.

In the past, it is said that there was a custom of receiving a new half-cloth from a master or husband at the beginning of each year.

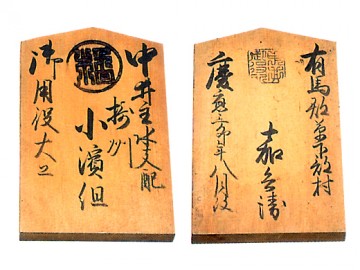

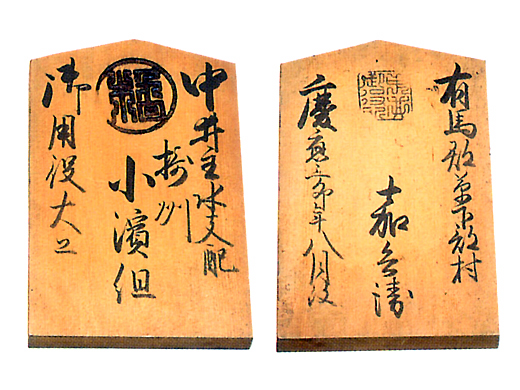

License

Customs and literature documents: Late Edo period

Construction work during the Edo period was controlled by the bakufu (Japanese feudal government headed by a shogun) and the domain, but the Nakai family, who had been successful in the early days, was assigned to the six provinces of Gokinai (Yamashiro, Yamato, Settsu, Kawachi, Izumi) and Oomi. The carpenter group in the jurisdiction was able to participate in the construction for the first time with the approval of the Nakai family, and the license was a proof of the qualification.

Tool catalog

Customs and literature materials Carpenter Tools catalog and woodblock prints Showa period

Catalog of carpentry tools for mail-order sales from before and after the war and woodblocks used for printing. It is from Katori-ya, a long-established store that opened in Edogawa-ku, Tokyo in 1923 and continued to operate even after the war. This is an interesting material that shows the culture of carpentry tools in the process of changing from woodblock printing to photographic plates.

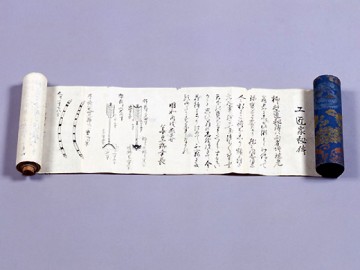

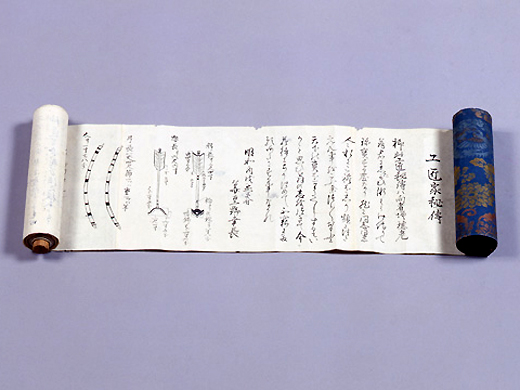

Transcription book (Kiwari book)

"(Secretary of Kashiwagi Ihei Masaru)" (Kiwarisho) written by Ihei Kashiwagi and Masatora in the 17th century

A secret book-style scroll that describes the method for assigning dimensions of each part of the building (wood split art). It was handed down to the Kashiwagi family, the leader of the Edo shogunate Kobushinkata, and there is a secret book that it was handed down to Taroemon Masatora by Ihei and others in 1689. The five volumes consist of 'Gosho-sama,' 'Jinja nobe,' 'Butsuden nobe,' 'Monnobe,' and 'Tonobe,' and are important materials for understanding architectural techniques and carpentry organizations of the Edo period.

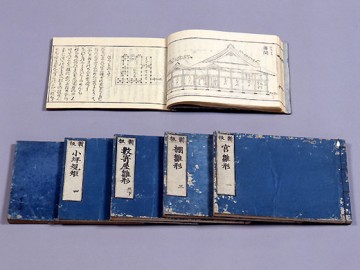

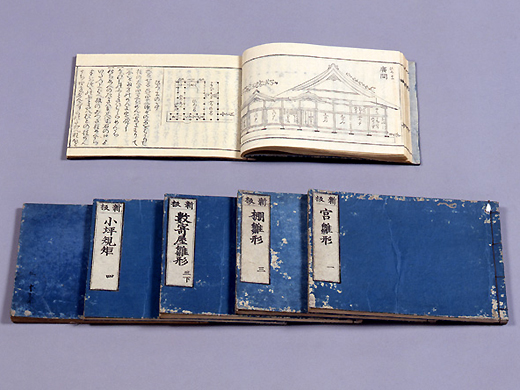

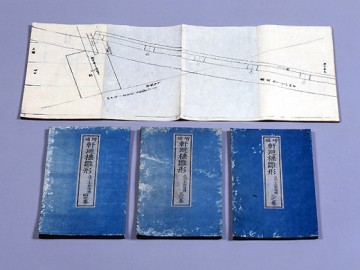

Woodblock book (Kiwari book)

Customs and literature materials Woodboard book "Carpenter Hinagata" (Kiwari Hinagata Hon) 18th century

Kiwarijutsu, which was a secret treasure of the Takumi family, was published in the Edo period and became widely known. This book, which opened in 1717 (1717), consists of a set of six books, consisting of "Miya Hinagata", "Samurai Hinagata", "Sukiya Hinagata", "Kinori Kotsubo", and "Kinori addition". The three books, Miya, samurai, and shelves, are based on the three new editions published in 1658 (1658), and there is no change in the content.

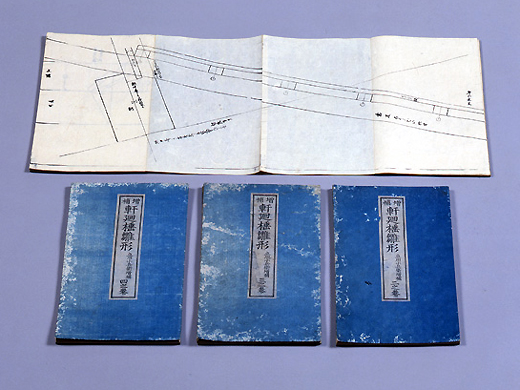

Woodblock print book (Book of Japanese Stereotomy)

Japanese Stereotomy Hinagata (Book of the 18th century) by Tachikawa Kohei, 18th century

Japanese Stereotomy is a technology that draws the state in which each member is three-dimensionally combined on the head, and draws it flatly. In particular, the area around the eaves of shrines and temples architecture was very difficult because the members joined diagonally and warped. In the late Edo period, Hinagata books describing the esoteric Japanese Stereotomy around the eaves were published. This book is written by Kohei Tachikawa in 1764.

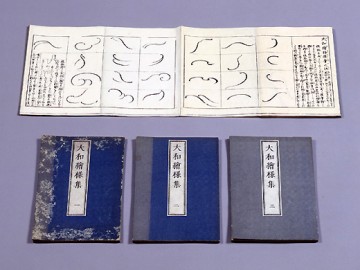

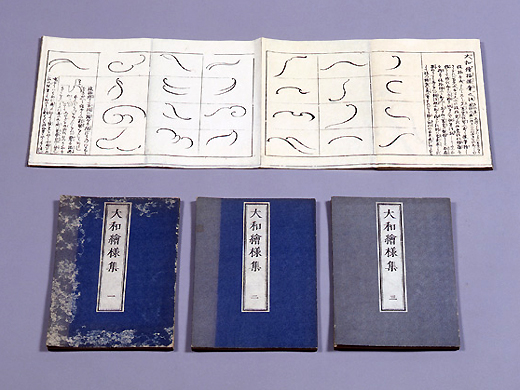

Woodblock print book (picture collection)

Wooden book "Yamato-egata shu" (picture doll book) written by Tachikawa Kohei in the 18th century

Pictures are sketches for sculptures and their patterns. In the mid-Edo period, pattern books and template books, which collected various sketches, began to be published. This book is a representative of it, written by Tachikawa Kohei in 1763 (1763), and consists of four chapters.

Transcription book "The Secret of Artisan Family" (ceremonial book)

"The Secret of Artisan Family" (ceremonial book) written in the Edo period

The custom of performing rituals at each milestone of construction work has been handed down to the present day, such as the ground-breaking ceremony and the upper ridge ceremony, but more than 20 rituals were held in the old tradition of shrines and temples. Managing this ceremony was also a job of carpenter ridge masters. There were many promises in the ceremony, and in the Edo period, scrolls and model books describing the form and procedures began to be created.

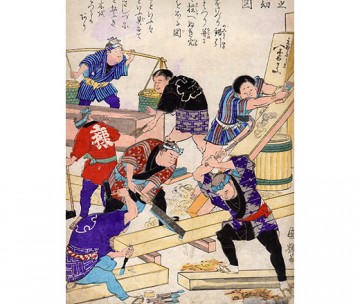

Woodblock prints

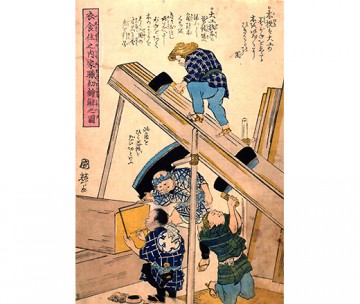

Woodcut prints of the customs and literature materials 'Kimonoku Suminouchi family shikiyo-e ko-e zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu

A collection of diagrams published by the Ministry of Education in the first year of the Meiji era as a commentary map for schoolchildren. The artisans from the late Edo period to the early Meiji period are vividly depicted. Basic carpentry work such as ink hanging using an ink pot, chona hanging, sawmilling with saws, carving with a chisel, and plane cutting are depicted.

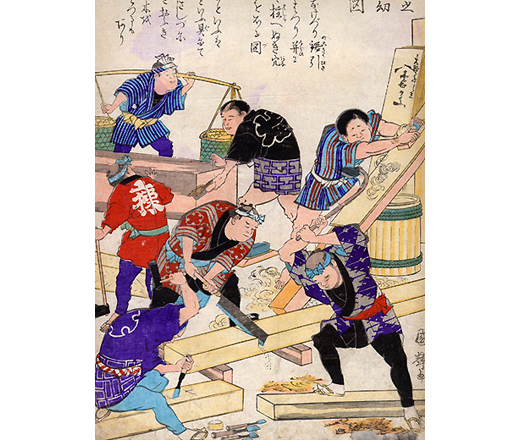

Woodblock prints

Woodcut prints of the customs and literature materials 'Kimonoku Suminouchi family shikiyo-e ko-e zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu zu

A collection of diagrams published by the Ministry of Education in the first year of the Meiji era as a commentary map for schoolchildren. The artisans from the late Edo period to the early Meiji period are vividly depicted. It depicts the wood grinding using Maebiki-oga Wide Blade Ripsaw and the carpenter inking the square wood.

Woodblock prints

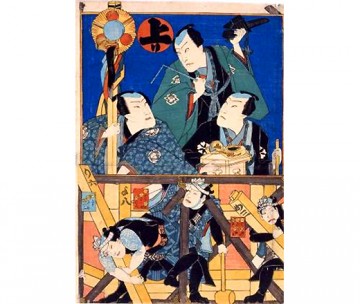

Woodcut prints "Hanayagura ridge upper Kotobuki-goroku" in the middle of the 19th century

A multi-colored woodblock print depicting the state of the building up in a twin-rox format. One of five of them. You can understand the customs of carpenters during the Edo period. At the bottom, there is a state of construction (Kumi-raising), and at the top there is a state of carpenter performing rituals.

Basic information

Special Exhibition

Permanent exhibition